Recognized by artisans and literati centuries ago, these characteristics of the Zisha or purple clays help to make Yixing pots especially well-suited for brewing tea. Excavations have shown that the composition and structure of the clays used in making authentic Yixing teapots today closely resemble those used in pots from the 1500s and later.

Yixing Teapots are made by a very special unglazed clay material called “zisha” clay. The yixing purple clay teapot is reputed as the “first of all tea-sets in the world” for its unique material and characteristics.

Yixing clay has very special characteristics chemistry composition and texture, a 4% 0f the water absorption rate, a very low thermal conductivity, and other unique qualities, it already is confirmed and is received that Yixing clay is best raw materials for made teapot in whold world. When properly refined and fired to a high (but sub-porcelain) temperature, it produces a type of pottery that is slightly absorbent. Legend has it that if you have prepared tea in an Yixing teapot many times, you can reach a point where by adding boiled water alone you can make tea, because the teapot itself holds enough of the tea flavour.

The characteristics of yixing teapot

Pottery made from purple clay is earthy and refined, and displays the ingenuity of the craftsman; it is full of cultural flavor characteristic of the East. The ancients praised that “pearls and jade can be found everywhere but there is only one soil like that at Yangxian(Yixing) Shitou.” Therefore, one can say that purple clay soil is a national treasure endowed by the heavens.

The ancients praised tea drinking thus: “water is the mother of tea and teapot is the father” and “Yixing clay teapots are the best”:

1. One of the special attributes of Yixing teapot is the ability to retain heat. Yixing clay teapots conduct heat slower so can hold the heat longer, and it doesn’t burn the hand if you touch it.

2.Small pores produced in the clay during firing retain both heat and flavor, the lid keeps the steam in and yet does not smother the aroma, and the low shrinkage rate of Yixing clay allows the skillful potter to make a closely-fitting lid that inhibits oxidation thus heightening the tea flavor.

Yixing teapot can keep tea’s heat, primary colour, aroma and taste. This is proved by the test: the fine qualities of tea will been retain for 5 days if you use yixing teapot. But it only can retain 3 days if you using other ceramics teapots.

3. The Yixing teapot is free of lead, arsenic, cadmium, and other toxic materials. Yixing ware is unlike other unglazed earthenware teapots. The Yixing teapot has a fine and solid texture, a four percent water absorption rate, a very low thermal conductivity, and a double air pore struction which enhances the pot brewing properties. The principal standards for evaluating a teapot brewing quality are the color of the tea soup produced and the level of tea phenol, caffeine, and aminophylline. The performance of the Yixing teapot is far superior to that of the standard teapot with respect to all four of these criteria. Not only are the Yixing teapots beautiful and unique works of art, but also, they are excellent brewing vessels. in fact,yixing teapots exceeds the strict standards imposed by china’s pottery reserch institute and are also approved by the usa”fda”.to ensure this high standard of quality.

4. Tea inside it does not seep though no glaze is applied on its surface, tea brewed in it tastes rich and mellow for the Yixing teapot is porous. After firing, Yixing tea pot is solid and impermeable, yet porous enough to “breathe”. A Yixing teapot enhances the tea brewed in it with respect to colour, smell, and taste. Its walls seem to absorb the tea and keeps fragrance. In summer, it keeps tea overnight without spoiling. With hot tea inside, it does not scald the hand with purple sand being a slow heat-conductor. But in winter, it may serve as a hand warmer and may be left on a low fire to make certain types of tea which need simmering. To the Chinese tea connoisseur, it is the “ideal teapot”.

5. Purple clay pottery is like wool: thick, snug, neat, pure, classy; and it is luminous as a piece of antique jade. Because the yixing teapot’s surface is fine and delicate, the more you use it, the shinier it becomes, the newer it looks, and the more energy it seems to exude. The colors of the clay are rich and varied, smooth and elegant, earthy and stable.

6. Because of its special composition, purple clay is also good for making flower pots since it can let light through and absorb water, which prevent roots from rotting.

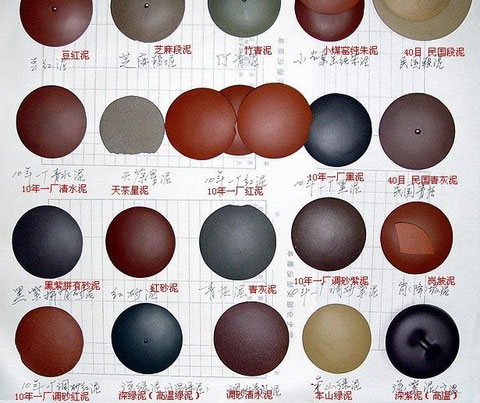

Yixing teapot each piece is shaped by hand on a potter wheel and left unglazed, both because it makes better tea and because doing so allows the color of the clay to shine through. Highly prized for its porous nature, which is excellent at absorbing the flavor of tea, Purple sand or clay does not really in purple color only, it depends on the layering from the ground, different layers has different color, Yixing clay occurs naturally in the characteristic colors: light buff, cinnabar red and purplish brown. It can have many natural color after fired.

Yixing clay variety and basic info

Clay of Yixing are mainly Jiani, Nenni and Baini.

Jiani is dark solid clay mostly used for making ceramics, vase etc..Nenni is yellow-ish soft clay. Baini is white clay that is mainly kaolinite, used to make porcelain or ceramic. But the real clay used to make yixing teapot is zisha, there are actually three different varieties of Zisha.

The most common of these are the Zini or purple(rose-brown) clays. The other two more rare clays are know asBanshanlu(light green) or creamy white to light-brown clays and Zhuni or red clays. Chemically, all are composed primarily of quartz, kaolin and mica and contain high amounts of iron oxide, which lends the clays their purple-red color. Zisha clays are also fairly sandy. All are from local mines and are composed of natural minerals. They are hidden between rocks and ordinary pottery soil, that is why they are sometimes called the “soil within the rock” and the “soil within the soil.”

The three soils are mixed according to need and the color desired. Then, it is fired at various temperatures depending on the soil composition.

• Darker colored clay is more rich but the color gradations range from: sky green, millet, deep purple, pear skin, cinnabar purple, flowering apple red, green gray, ink green, to bluish black, etc.

• There are colors that can be described as: modest purple, delicate red, mature green, chromatic black, and florid gray, etc., that are truly elegant.

• Other colors are created by mixing these three clay.

• A principal factor in determining the depth of the color is the concentration of iron in the clay.

Zini (purple, fired is usually brown-ish) exists as small amount inside Jiani ore bed.

When Zini contains so much manganese that becomes dark dots after firing, it’s called Hei Xing ni(aka Tie Xing ni, Hei Xing Sha).

Qing Shui ni originally is about method of clay manufactering, pure clay without any mixing, usually mined from mid part of ore bed, common clay.

Di Cao Qing is from deep inside, usually reddish brown. Di Cao Qing is usually darker and heavier than Qing Shui ni.

Pin Zini means mixed Zini.

Luni (aka Ben Shan Lu ni, Benshan means original mountain that is Mt. Huanglong) is sort of mutant silica dots, evenly found from Jiani ore bed, very rare.

Duanni is also rare, coincidently when co-exists with Luni and Zini. Most Duanni today however, is from Tanxi or Hufu or intentionally mixed with Luni and Zini. Zima(sesame) Duanni has many dark dots that resembles sesame. Bai Ma Zi ni is very similar to Luni after firing but not smooth and lots of grits.

Hongni is from Nenni ore bed.

Zhuni is very yellow ore, more yellow, better Zhuni. On Zhuni, is special clay cos it has different characteritics than other clay. Unlike other clay(Huang Long mountain), birth place of Zhuni is Zhao Zhuang mountain, which is Lao Zhuni. Most of Zhuni today is from Xiao Mei Yao (near Huang Long mt.) and Hu Fu (aka modern Zhuni).

Xiao Hongni is darker than yellow.

Da Hongni is from Jiani ore bed, basically Zini.

Da Hong Pao ni was from Huang Long mt., very popular during Qing dynasty. Real Da Hong Pao ni however, would sell no less than 500 USD. Most of DHP ni is from Fudong area recently.

On Pin Pei (mixing clay)

Pin Pei can be classified as clay-mixing and chemical ingredient-mixing. On former one, can actually enhance the quality of clay and plasticity.

Great masters such as Si Da Bin or Hui Meng Chen were actually masters of Bing Pei.

For example, the most expensive clay like Ben Shan Luni can’t be used for teapot making without mixing with Zini, unless it’s used for decoration.

The sought-after clay like Di Cao Qing, is actually better in smoothness and color after mixing with Qing Shui ni or Zini. Pure Di Cao Qing not only requires high

temperature (1240C) to be fired but also unglossy and dark. However, Zhuni is exception.

Latter is mixing with ingredients such as manganese oxide, iron oxide, copper oxide etc..

It looks good when first exhibition, but doesn’t earn natural patina after

long time of usage.

Also, these clays are actually fired at low temperature and smell a lot.

Chemical ingredient-contained clay

History of this method dates back to ROC.

Due to hazardous effect and need of effectiveness, amount allowed to use limits less than 0.5%.

*Mixing with copper oxide makes artificial Duanni (yellow)

*Mixing with cobalt/chrome oxide makes bright greeness or so-called Muo Luni

*Mixing with manganese oxide makes Hei Xing ni(black-star clay), Qing Hui ni(green-grey clay) or Heini(black clay) etc..

*Mixing with iron oxide enhances redness, used for coloring of Zhuni

Chemical used clay mostly doesn’t show extra dots of natural minerals but things get more

complicated if mixing it with natural clay

Characteristics of various Yixing clay

Zisha, or purple clay, from which Yixing ware is made, is found throughout the hilly southern area of the Yixing region. The particular qualities of this clay substance set the Yixing apart from other unglazed earthenware teapots. Geologists have pinpointed the origins of Zisha in the area compressed sedimentary lake deposits.

Purple clay soil is a kind of special pottery soil that is very fine and delicate, and that contains high amounts of iron. Its molecular structure is different from that of common pottery and porcelain soils. After being fired at 1200C, the structure becomes like fish scales and has the ideal rate of density and pores. The surface of a pottery piece is fine and delicate and does not need to be glazed. When used for making tea, no chemical reaction will take place. Therefore, using a purple clay teapot for tea will allow you to savor the full flavor, color, and aroma of the tea.

Yixing clay, a kind of ore body, is as hard as rock when unearthed.

1. Yixing clay soil is excavated by tunneling, piled on the open air, blown by wind and struck by rain for months, it will turn into small loose grains, as small as soybeans;

2. Then it has to be crushed to powder by a stone mill;

3. Sifted, mixed with the right amount of water, left in a cool shady place to stale;

4. Pounded (churned in a vacuum), in order to reach the ideal quality for molding;

5. But before it is used to make vessels, it is to be beaten with a wood hammer for tens of times.

Each Yixing clay has a different ideal temperature of firing, different temp has to do with crystallization. Crystallization is important cause it will

lead the clay no smell, no blot, better patina and better functioning.

1) Zini

Normal temp of firing is about 1150~1180C, Zini is rather easier clay to treat (Di Cao Qing for exception). Easy to craft, no worrying about firing. Higher temp-fired Zini

turns grey-ish purple.

2) Luni

Minimum temp for Luni is about 1180C, lesser temp will lead Luni famous ‘blot’ or ‘crack’. I’ve seen some sellers recall Luni pots caused by

amateur firing. Luni is a clay that has no plasticity, so firing is very complex and requires experience. So to solve this complexity, potters make ‘Duanni’ by mixing with

Zini. Low-temp fired Luni is beige and sees a hint of green after 1200C (Duanni as well).

3) Zhuni

Normal temp for Zhuni is less than 1100C, Zhuni is of very small particle so sees crystallization at lower temp. Zhuni is a clay that shows highest rate of shrinkage.

Normally over 20% and Zhuni is of mud-like clay. That makes working on Zhuni different, should make it quick with less touching. Because more trimmed or touched spot will be reflected after

firing. And that’s one way to discern a real Zhuni, to find a trimmed or joined spot.

4) Yao Bian (kiln color changed)

Yao Bian pots are not seen often in western market, but is one form of Yixing clay as well. Originally Yao Bian pots were of natural wood-fired effect caused by lack oxygen. Modern day Yao Bian

pots are of course from intention. To make this effect, potters fire pots even up to 10 times, or mix among fire-endurable clays and fire up to 1300C, with potters’ own method

The characteristics of the yixing clay may be summed up into following aspects:

The plasticity of ready clay, the hardness of the shaped clay-body and the low contraction rate make it possible to create pottery of various kinds, fantastic designs and different lines. For hundreds and thousands of years, generations of artists have kept on experimenting and exploring and added splendour to the civilization of mankind.

1.Of high plasticity. With a liquid limit of 33.4%, modeling limit of 15.9% and an index of 17.5%, purple-clay is of high plasticity and can be made into various shapes of different sizes. It has strong adhesion, but is not glutinous in hands and implements. The mouth, handle and the teapot body can be made separately before they are stuck together and polished with clay. The clay pieces of square vessels may be got together with grease clay, too. Such a large capacity materially enables the pottery artists to fully display their creative intention and give free play to their artistic techniques.

2.Of low contraction rate. From a claybase to a fired product, its contraction rate is only about 8%. It also has a wide range of firing temperature, a low deformation rate and a strong intensity of the raw chaybase. So the teapot cover suits the mouth very tightly, the contour is up to standard and can not be twisted. The handle may be designed thicker than that of a porcelain pot, and the round surface of the pot mouth is in proportion with the mouth. Besides, the clay can be used to make open-mouth vessels and teapots with mouth and body of the same width.

3.Purple-clay can be processed into pottery without any addition of other materials. The produced pottery have two layers of gas hole construction: close-mouth layer, that is the gas hole inside the nodule body; and open-mouth layer, which refers to the gas hole group around the nodule body. The two layers of gas hole provide the purple-clay pottery with fine ventilation. In addition, the tiny gas holes of high density possess strong absorption, which the glazed ceramic teapot lacks. Meantime, precisely and reasonably shaped, the yixing teapot, with its mouth and cover fitting perfectly, has a displacement error within a tolerance of less than 0.5mm, which decreases the possibility of the air mixed with germs entering into the pot. Therefore, the colour and flavour and fragrance of tea may last for quite a long time and delay the time when the tea goes bad. Furthermore, purple-clay teapot has the capacity to tolerate sudden heat and coldness. Even if boiling water and cold water are alternately poured into it, it will not explode or crack.

4.Another uniqueness of purple-clay is that it needn’t be glazed after it is shaped. It is smooth and shiny. After it is handled and caressed for a long time. It will send out dim light. While pottery clay of other texture can not be compared to it in this aspect.

茶者,南方之嘉木也。

Tea grows in the south of China.

---Famous Tea Scholar Lu Yu Tea Sutra.

茶者,南方之嘉木也。

Tea grows in the south of China.

---Famous Tea Scholar Lu Yu Tea Sutra.

Write a comment

George Ingraham (Thursday, 26 January 2017 07:51)

Just want to say thank you for this information....